Products

Data acquisition system

BSI suite

Our spectrometer-based BSI-1XX interrogators have independent optical channels to measure up to 40 wavelength-division-multiplexed fiber Bragg gratings (FBGs) cascaded per optical channel at high speed.

Standard BSI-108, BSI-116, BSI-132 and BSI-164 units feature 8, 16, 32 and 64 independent channels, respectively. Several hundreds of sensors can then be interrogated with a single device!

BSI-108 and BSI-116 units can be assembled in a benchtop frame or in a 19-inch rack. Other units are exclusively provided in a 19-inch rack. In terms of optical connectors, FC/APC or SC/APC are standard.

This suite of interrogators is suitable for static and dynamic applications like temperature sensing, structural health monitoring or condition monitoring.

Such devices are provided with a fully customizable interface that can be optimized depending on customer’ specifications.

FBG

B-SENS has accessed to up-to-date facilities to manufacture Bragg gratings in different single-mode fiber types.

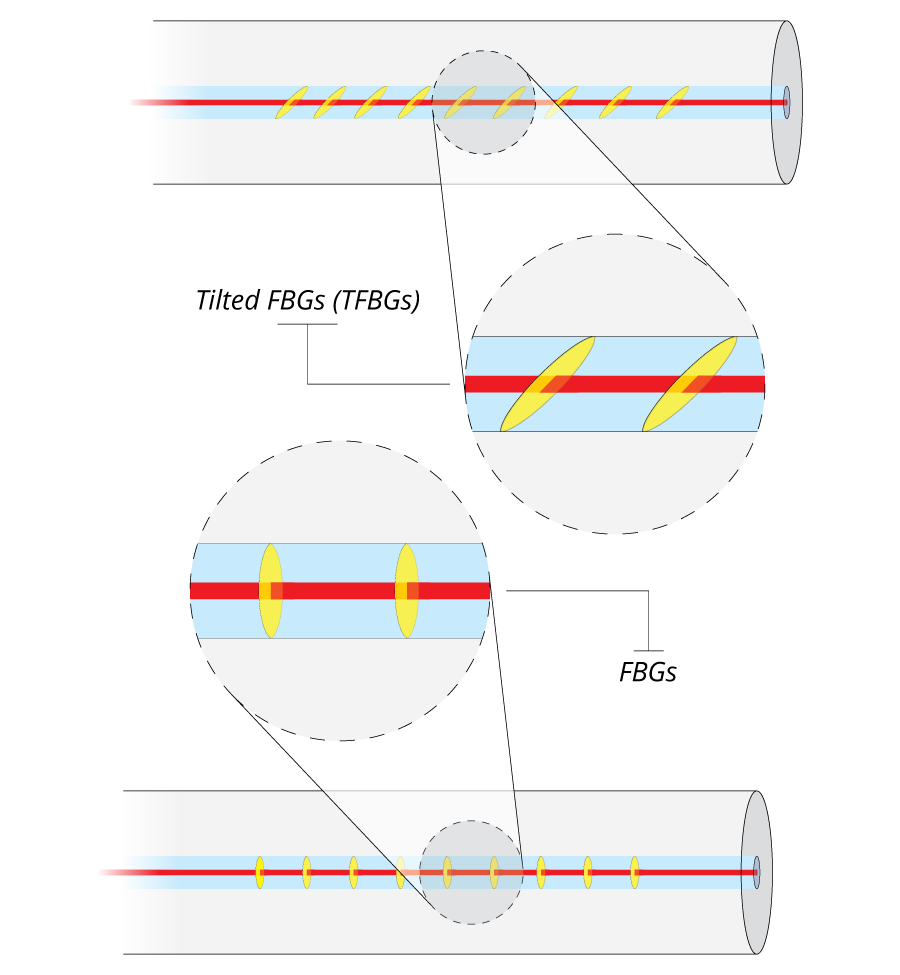

Uniform and tilted Bragg gratings can be produced by the phase mask technique or the Lloyd mirror configuration.

Uniform gratings can be used as filters in telecom applications or for temperature and strain sensing.

Tilted gratings enable refractometric and multiparameter sensing.

The following specifications can be reached:

These gratings can be supplied bare or packaged and/or connected (FC/APC or SC/APC).

FBG sensors

(High) Temperature

FBG temperature sensors are suited for a large range of applications where quasi-distributed static or dynamic measurements are essential. They are provided with PTFE or stainless steel capillary tubing, depending on the target temperature range.

For high temperature sensing, a safe & continuous use is ensured up to 650 °C. Sensing up to 1050 °C can be achieved depending on the actual conditions.

These temperature sensors ensure intrinsic immunity to electric sparks and electromagnetic and radio-frequency interferences. They combine compact size, high resistance to corrosion and harsh environments, and a long-term reliability.

A single optical fiber can replace tens of temperature probes!

Strain Monitoring

FBG axial strain sensors are suited for a large range of applications ranging from structural health monitoring to condition monitoring.

They are either embedded in the structures (concrete, composite, …) to monitor or glued in their surface.

These sensors ensure quasi-distributed static or dynamic strain measurements. They are intrinsically immune to electric sparks and electromagnetic and radio-frequency interferences. They combine compact size, high resistance to corrosion and harsh environments, and a long-term reliability.

A single optical fiber can replace tens of strain gauges!

B-SOFT

B-SENS data acquisition systems are provided with an executable software that processes the raw data in real time and yields the measurands (temperature, strain, gas concentration, …). This software generates .txt files with the processed data as well as visuals (dashboard).

Data communication and cloud computing can be provided.

This software can be adapted to meet customer specifications.